Case Study: COVID-19 Causes Discontinuation of Product's Main Microprocessor

Development of our client’s motor drive assembly used in an optical coherence tomography (OCT) application was progressing smoothly enough when COVID-19 hit. Our original plan was to go into first in human with a main board that received the amazing Teensy 3.2 as a daughter board. With an ARM Cortex M4 processor, robust firmware libraries, and – most importantly – small size, Teensy 3.2 was perfect.

But alas, when faced with the pressure of the COVID-19 response, NXP/Freescale was forced to significantly de-prioritize fabrication of the main processor for these boards, so we were asked to find a solution.

Perhaps PJRC has a newer model we could drop in? Now that the COVID dust has settled and mostly swept away, the answer is yes, Teensy 4.0. But at the height of the COVID lockdown, these too were unavailable. Dang!

After trying to find a path of least resistance that did not involve a big design effort, it became clear we needed to:

- Select ASAP a microcontroller that would be available after the COVID drama was over and also available to meet the immediate need.

- Buy at least 100 of them to store in our client’s apocalypses bunker (controlled component inventory cage).

- And design a new main board that integrates these precious little black squares with the Maxon ESCON 24/2 controller.

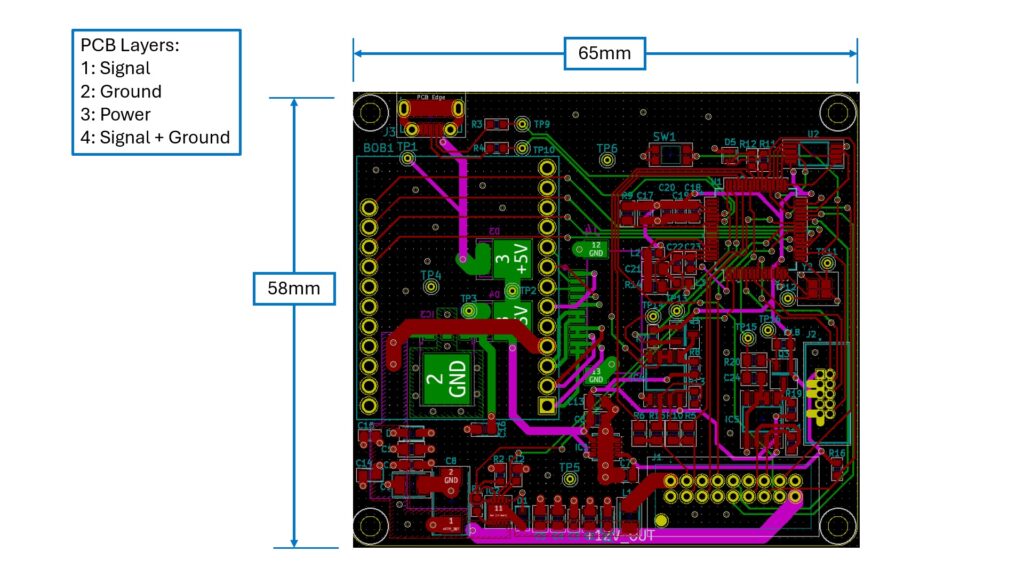

The finished design – now in use – features four layers to shield EMI while keeping it simple, the ESCON 24/2 driver as a daughter board, non-standard interconnections to slow would-be hackers from discovering it’s secrets, and an easy to get main processor, all within a small footprint.