Case Study: Simple Recipe Control for Automated Dipper

Our client needed a dip coating machine that didn’t cost $350,000 to apply hydrophilic coating to their catheters. These machines have four basic elements as follows:

- A gearmotor and driver operating under position and velocity control.

- A user interface to select recipes and start/stop the dipping cycle.

- A means of adding or modifying recipes.

- And a framework to hold it all together.

It is possible to make such a system complex enough to justify a large price tag, but startups generally can’t tolerate such excess. Our client needed the basics, which can be a challenge once you enter the PLC industrial complex. These extremely robust industrial systems are designed for a scale that is inappropriate for small startups.

We were asked to keep it simple. Our solution is an example of what Paul Graham talks about in his now legendary essay: “Do Things that Don’t Scale“.

Here’s the control box interface of our de minimis dip coating system. The cost was low enough our client bought two!

The biggest single expense with such systems is often the engineering hours required to program the Human Machine Interface, or HMI. HMI costs were minimized with the use of physical buttons and limited 4-line character display.

Probably because it is so simple, we have not received any complaints our interface control-boxes have failed

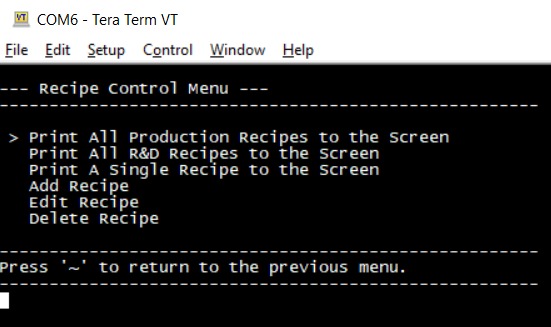

To add or modify recipes, things get a bit more complicated, but we still leverage very old (read simple) tech. When a manufacturing engineer wants to change or add a recipe they boot up their Windows, Apple, or Linux laptop, connect a USB cable to the engineering port, load up their favorite VT100 emulator, establish a serial connection, and then they are greeted with the menu shown at right.

If we enter into recipe control we see something like this.

And if we went back to the Root Menu and the selected “About This Firmware” we’d see something like this.

Admittedly, a graphical interface would be nicer, but it’s a question of opportunity cost. IE, what next problem are we not addressing because we are making this menu look really nice. For startups, getting started on the next problem (opportunity) is almost always a better use of our time.