Case Study: Heavily Worn Aluminum Injection Molding Tool

Our client was starting to get traction on their novel mechanical atherectomy device and production volumes were increasing. Sadly, the aluminum molds used for the plastic handle components were starting to wear and cause issues with the internal mechanism spinning at over 10,000 RPM.

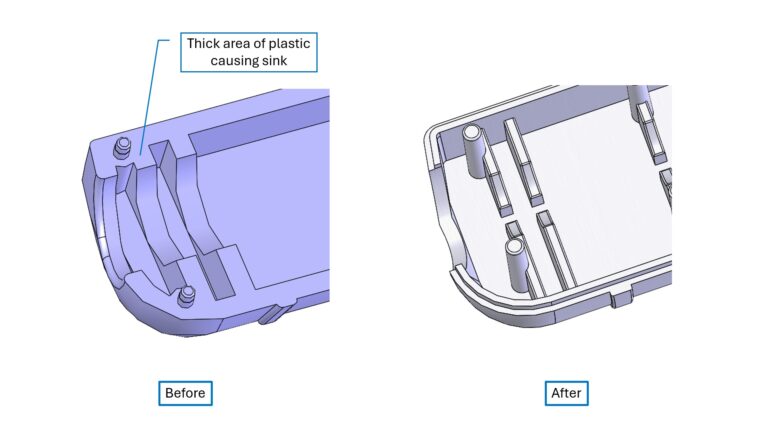

Also, the original design had thick areas of plastic that caused deep sink marks, making it looks less like a refined product.

We were asked to move the part to a hardened steel mold and fix the sinking. This task seemed easy enough, famous last words… There were hard internal-feature constraints because components inside the handle could not change. And, after the device is pulled from the sterile pouch in clinic, it is snapped into a separate motor drive unit, so external features couldn’t be adjusted either.

Our task was to change the handle without changing the handle.

After more SolidWorks than anyone should endure, a solution was found. The parts are molded in Bayer Makrolone Polycarbonate Rx2530, which has a recommended wall thickness of .040” – .150”. Our main wall was .045”, with ribs going down to .028”. Thicker ribs were preferred, but – given all the constraints – compromises had to be made!

High-resolution industrial 3D prints were ordered to confirm the design prior to cutting the hardened steel mold. Hopes were high! We received the parts and put everything together. To our horror, a slight twist of the assembly made the press-fit pins come out of their holes, resulting in the whole thing coming apart.

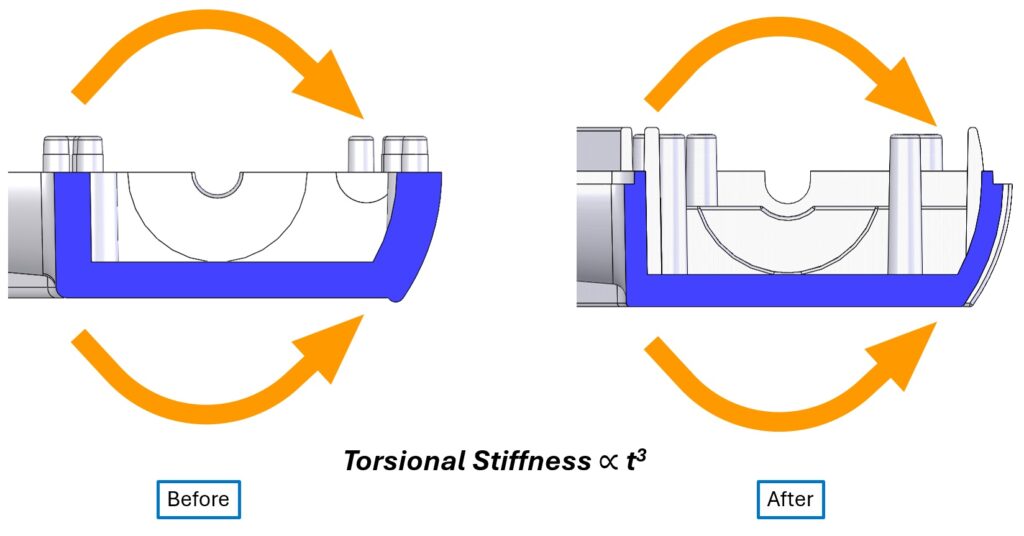

Since we needed to thin everything down to avoid sink marks on the outside, the torsional stiffness of the system dropped considerably. Though not a perfect analog, the cross-section of each handle half is similar to a u-channel, the torsional stiffness of which scales with the wall thickness cubed.

That means the “Before” handle half in the picture is roughly twice as stiff as the “After” one, in torsion.

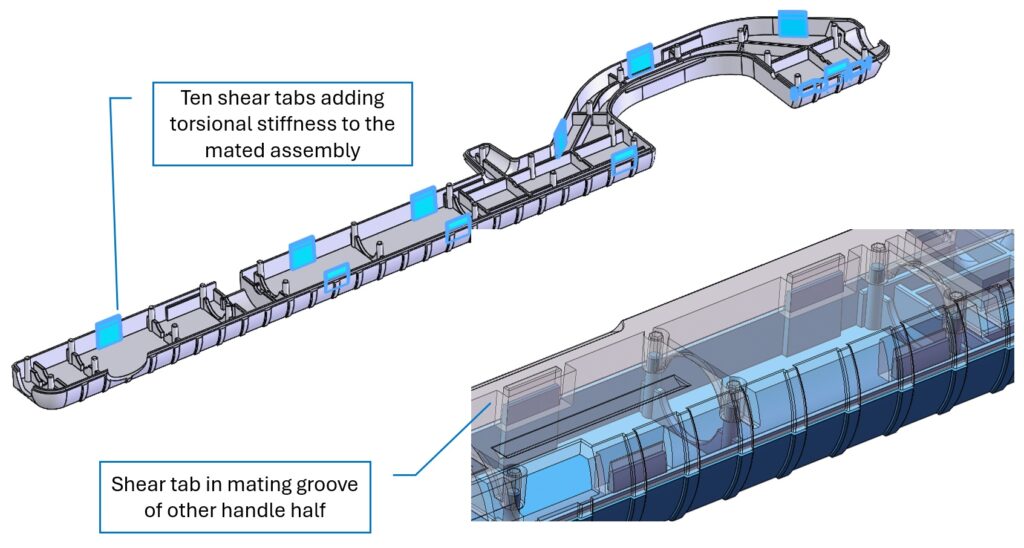

So how do we solve this? Enter shear tabs. These things worked better than expected. They are very thin in one direction but thick and stiff where needed. With a few of these tabs inside mating grooves in the other handle half, the thing got back its torsional stiffness.

Below are several pictures showing the effect of shear tabs. The tabs were removed from the handle assemblies shown at left.